Articles October 19, 2023

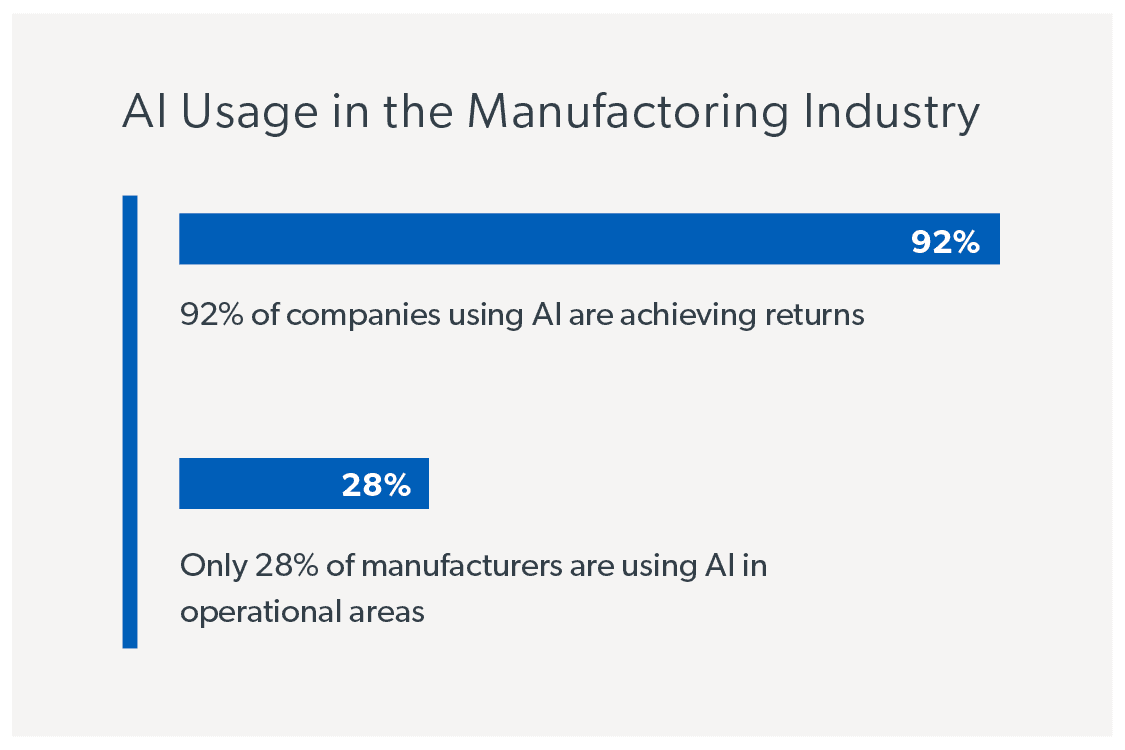

How AI-Powered Data Automation Can Transform the Manufacturing Industry

Optimize Your Whole Business

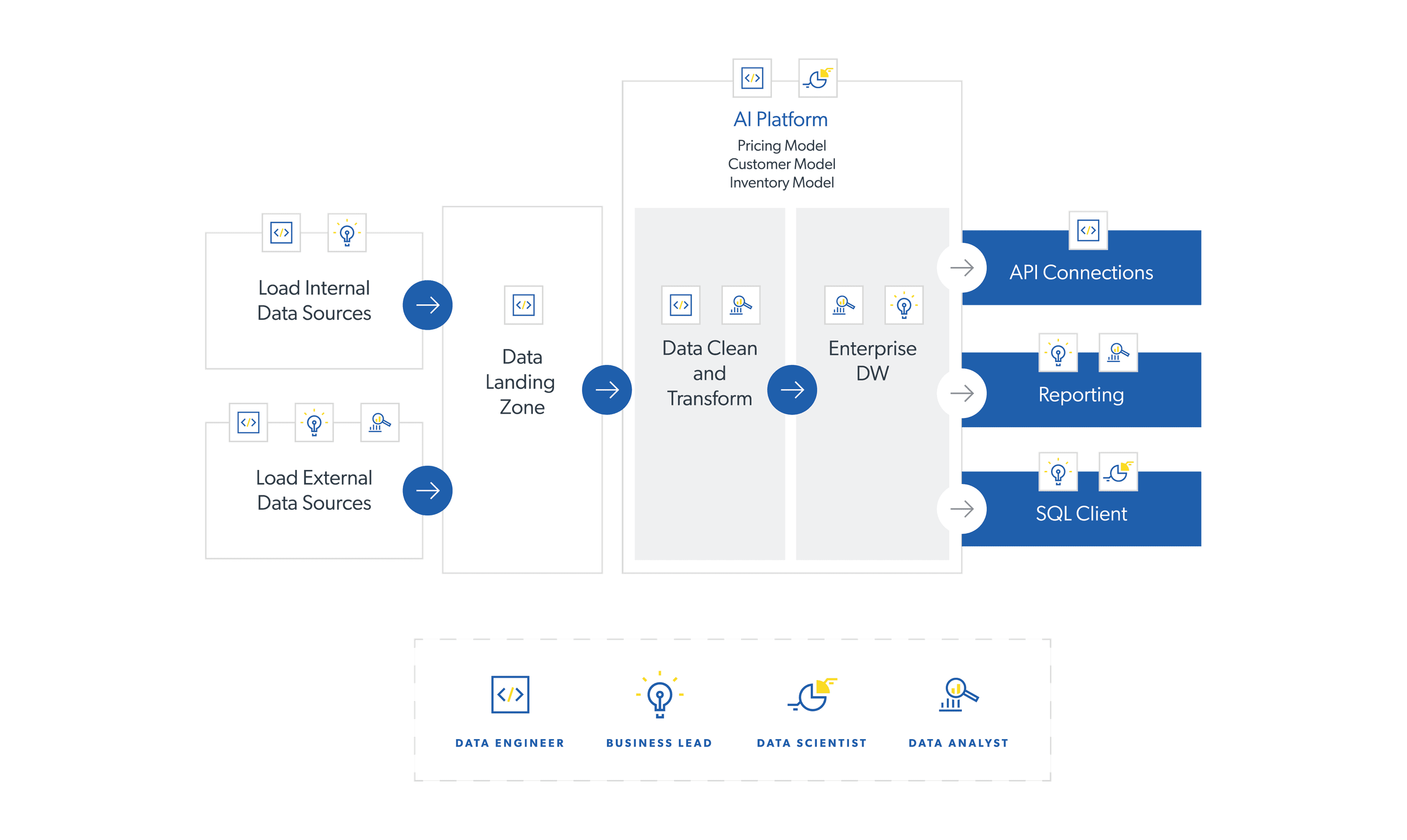

Data Orchestration

Cloud Data Platform

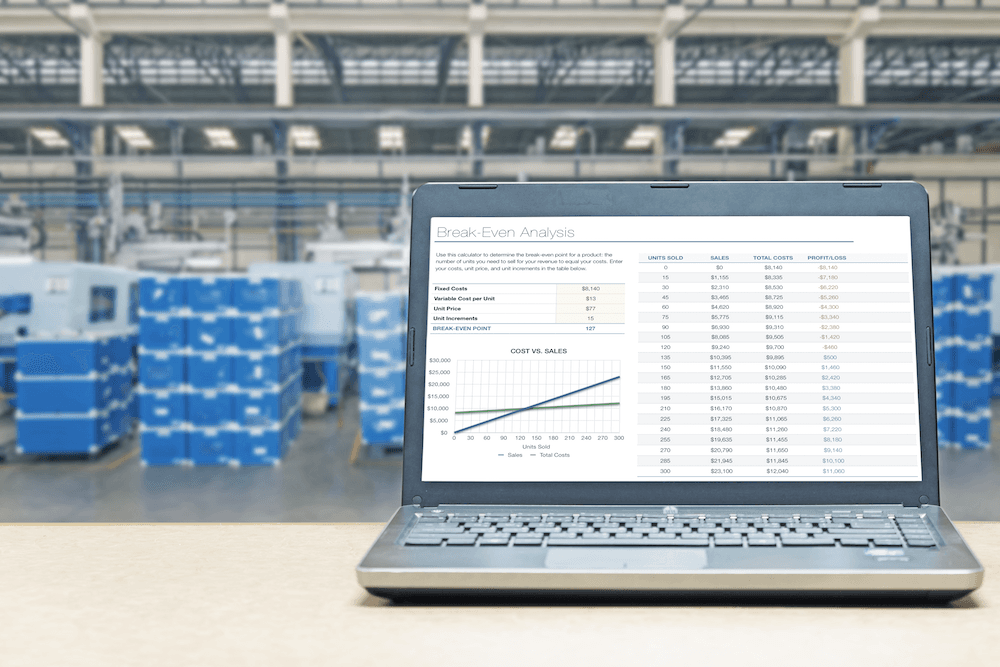

Optimizing Revenue with Data Automation

Optimizing Customers

Optimizing Inventory

Becoming a Modern Data Organization

Download this PDF

Learn More

Michael Monsilovich

Managing Director

As a Senior Account Executive, Mike serves clients within the Materials, Manufacturing, and Construction industries. Leveraging his understanding of industry-specific challenges and technology-driven solutions, he guides clients to use innovative IT strategies which enable operational efficiency and business growth.

Jason Hunter

Director

Jason helps clients define and achieve revenue-generating objectives by implementing data-driven, AI/ML solutions and by leading multi-functional teams of data engineers and data scientists across projects with a focus on data contextualization, delivery, and client satisfaction.